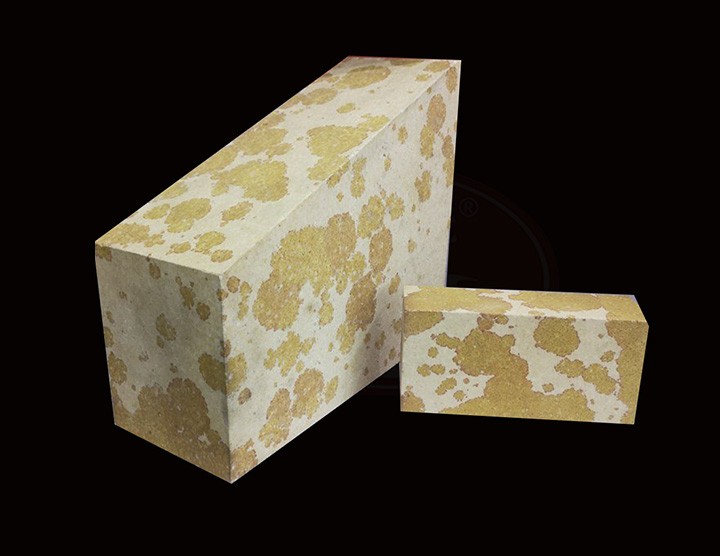

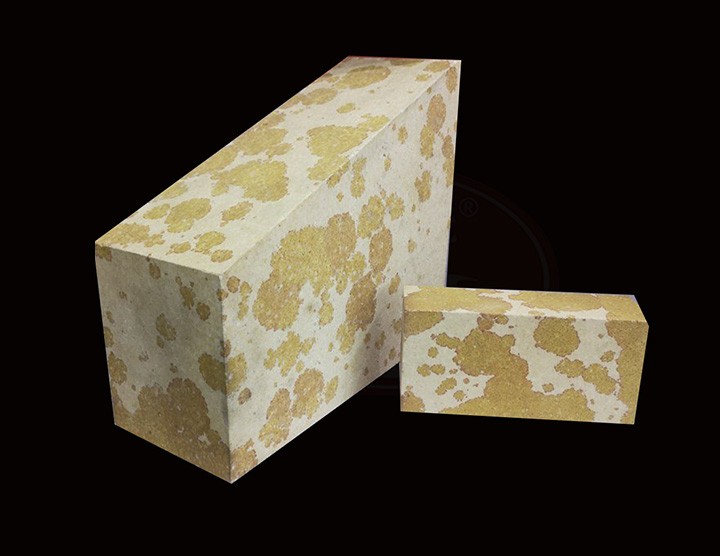

Silica brick series refractory brick:

1.Good thermal shock resistanceApplication:

1. High quality silica brick are commonly used in crown, parapet, hanging wall and runner of glass kiln;|

Silica brick series |

|||||

|

Product |

Zero expansion silica brick |

High quality silica brick |

Ordinary silica brick |

Lightweight silica brick |

|

|

Main component |

SiO2(%) |

≥98 |

96.54 |

95.6 |

92 |

|

Al2O3(%) |

≤0.2 |

0.3 |

0.95 |

/ |

|

|

CaO(%) |

≤0.01 |

/ |

2 |

/ |

|

|

Fe2O3+TiO2(%) |

≤0.1 |

0.58 |

0.65 |

/ |

|

|

Melting index(%) |

/ |

0.41 |

1.19 |

/ |

|

|

Apparent porosity |

≤16 |

17 |

21.6 |

≥50 |

|

|

Compressive strength at room temperature(Mpa) |

≥40 |

70 |

60 |

4 |

|

|

0.2Mpa load softening temperature 0.6%(℃) |

>1680 |

1680 |

1620 |

1620 |

|

|

Bulk density(g/cm³) |

1.85 |

1.9 |

2.31 |

≤1.0 |

|

|

Thermal shock stability (1100°C water cooling) (times) |

>30 |

/ |

/ |

/ |

|

|

Thermal conductivity W/m.k |

/ |

/ |

/ |

0.235(300℃) |

|

|

0.38(800℃) |

|||||

If you need our products please write down any questions, we wi